Copackaged Optics vs Pluggable Optics: Key Differences

Copackaged optics represents a fundamentally different approach to connecting optical and electronic components in network switches, challenging the pluggable transceiver model that has dominated data centre infrastructure for over two decades. The debate between these two architectures isn’t merely academic; it shapes billions of pounds in infrastructure investment and determines the capabilities of networks that underpin everything from cloud computing to artificial intelligence. Understanding the practical differences between these approaches helps network planners make informed decisions about technology adoption, operational costs, and long-term strategic positioning. The comparison reveals trade-offs that extend well beyond simple technical specifications.

Architecture: The Fundamental Divide

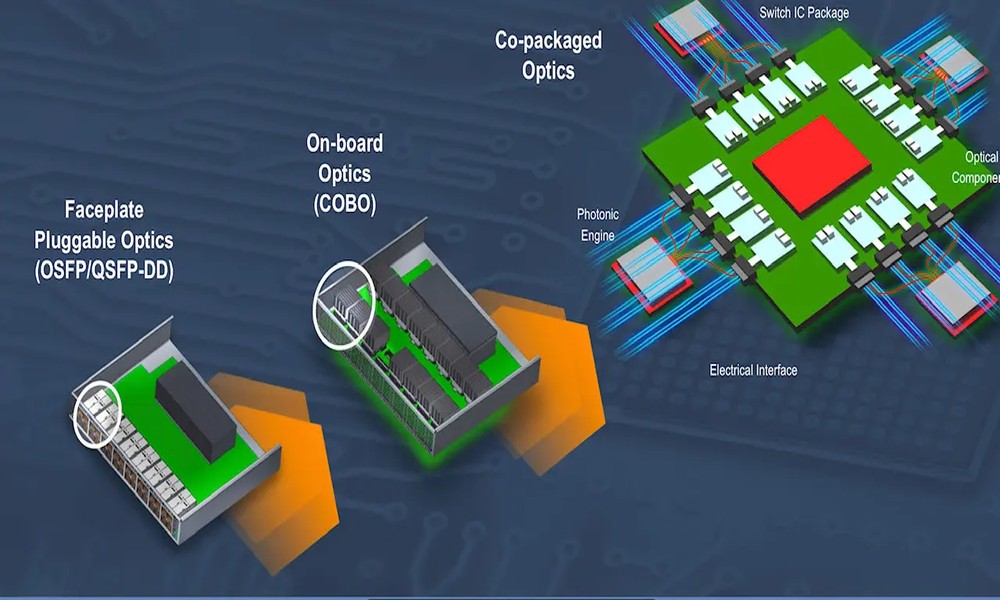

The architectural difference between pluggable and co-packaged optics couldn’t be starker. Pluggable transceivers sit in cages on the front panel of network switches, connected to the switching silicon through printed circuit board traces, connectors, and internal routing. This separation allows users to insert and remove optical modules as needed, providing flexibility and field serviceability.

Copackaged optical technology takes the opposite approach, mounting optical components directly onto the switch package alongside the switching chip itself. The optical input/output sits millimetres from the silicon, eliminating most of the electrical pathway that plagues pluggable designs. This integration sacrifices the convenience of field replacement but delivers performance and efficiency gains that pluggable architectures simply cannot match.

The difference matters because distance equals degradation in high-speed electrical signalling. Every centimetre a signal travels introduces loss, distortion, and timing uncertainty. Pluggable modules must compensate for this degradation through power-hungry signal conditioning circuits.

Power Consumption: Measuring the Gap

Power efficiency represents perhaps the most compelling difference between the two approaches. Pluggable optical transceivers typically consume 3 to 5 watts each at current data rates, with consumption increasing as speeds climb to 800 gigabits and beyond. Multiply that by 32 or 64 ports, and the optical interfaces alone consume 100 to 300 watts per switch.

Co-packaged optics dramatically reduces this overhead through several mechanisms:

- Elimination of signal retiming and conditioning circuits

- Shorter electrical paths requiring less drive strength

- More efficient thermal design with shared cooling infrastructure

- Reduced connector losses and impedance discontinuities

- Optimised power delivery without intermediate conversions

Real-world implementations show 30 to 50 percent reductions in total switch power consumption. For data centre operators paying escalating electricity costs and facing power capacity constraints, these savings translate directly to operational capability and profitability.

Density and Scalability

Pluggable transceivers compete for limited front-panel real estate. Each module requires physical space for the cage, adequate airflow for cooling, and clearance for cable insertion and removal. These constraints cap port density at levels determined by mechanical rather than electrical considerations.

Copackaged optics technology escapes these limitations entirely. Without front-panel constraints, switch designs can support hundreds of optical lanes, limited primarily by the capabilities of the switching silicon itself. This density advantage enables fundamentally different network architectures, particularly for applications requiring massive bandwidth between computational nodes.

The scalability implications extend beyond simple port counts. Co-packaged optic designs can optimise lane speeds and configurations for specific applications, providing flexibility that rigid pluggable form factors cannot accommodate.

Signal Integrity and Performance

The electrical path length difference between pluggable and copackaged approaches creates measurable performance gaps. Pluggable transceivers must drive signals across 15 to 30 centimetres of circuit board traces, through multiple connectors, and often through additional cable assemblies. At multi-gigabit speeds, these paths introduce significant signal degradation.

Copackaged optical designs reduce electrical path lengths to a few millimetres. The improvement in signal quality shows up in multiple ways: lower bit error rates, reduced jitter, better timing margins, and increased reliability. These benefits become increasingly important as data rates push toward terabit speeds where traditional approaches struggle.

Serviceability: The Trade-Off

Pluggable optics offer undeniable serviceability advantages. When a transceiver fails, technicians replace the module in minutes, minimising downtime. This field serviceability has long been considered essential for network operations, justifying the architectural compromises inherent in pluggable designs.

Co-packaged optics changes this model fundamentally. Optical components integrated into switch packages cannot be field-replaced. Component failures require factory service or complete switch replacement. This limitation sounds problematic until you examine the broader reliability picture.

Removing pluggable connectors eliminates common failure points. Better thermal management extends component lifetimes. Lower power operation reduces stress-related failures. The total cost calculation must weigh occasional field replacements against improved overall reliability and reduced operational costs.

Singapore’s Manufacturing Capabilities

Producing copackaged optics at commercial scale demands sophisticated manufacturing capabilities. Singapore has established itself as a key manufacturing hub for this technology, building on decades of expertise in advanced semiconductor packaging and photonics integration.

The precision required for optical alignment, the complexity of combining different semiconductor processes into unified packages, and the stringent quality requirements all play to Singapore’s manufacturing strengths. The nation’s infrastructure supports the full spectrum of production requirements, from component fabrication through final testing and qualification.

Cost Considerations

Initial costs favour pluggable solutions, which benefit from mature manufacturing processes and economies of scale developed over decades. Copackaged optical technology requires substantial upfront investment in new manufacturing capabilities and processes.

The long-term economics tell a different story. Reduced power consumption lowers operational costs throughout the system’s lifetime. Higher port density improves capital efficiency. Better reliability reduces maintenance and replacement expenses. The total cost of ownership calculation increasingly favours integrated approaches, particularly for large-scale deployments.

The Choice Ahead

Network planners face genuine decisions between these architectures. Pluggable optics offer proven technology, established supply chains, and operational familiarity. Copackaged optics delivers superior performance, efficiency, and scalability at the cost of changing operational models and accepting some degree of vendor integration during the technology’s maturation phase.