A Brief Guide about Linear Motion Guide

Mechanical components known as linear motion guides allow devices and machines to move in a straight line. Although there is a wide variety of linear guides, they all serve the same purpose: to provide low-friction, high-precision motion using a smooth, linear motion.

From producing semiconductors and medical devices to the automobile and aerospace industries, linear guides find widespread use. When it comes to linear guides, ball screw assemblies, LM Guide HSR Bearings, and linear guides are among the most prevalent types.

Linear guide systems are what?

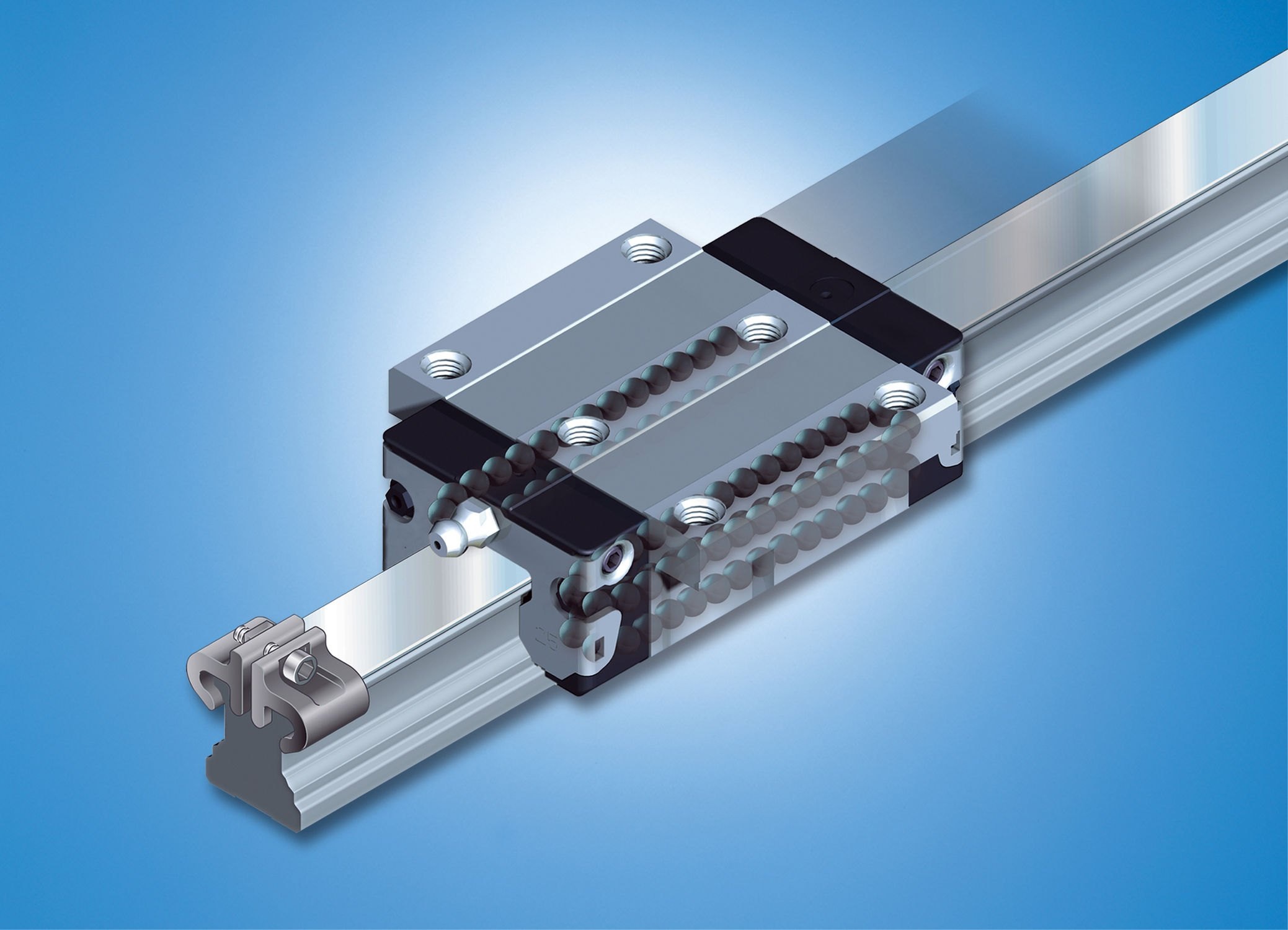

Mechanical guiding systems are available for parts to travel smoothly in a straight path, including the linear guide system. Typical components include a linear base, slider, and bearings (ball or roller). The slider is fastened to the element in motion, while the linear base is placed on a stationary surface.

The slider and the linear base can move with less friction thanks to ball or roller bearings. Many systems rely on the linear rail system, including conveyors and automated assembly lines.

How Are the Many Forms of Linear Guide Rails Classified?

Various linear guide rails are available, and each has its own pros and cons. Linear guide rails often come in the following types:

- Ball Bearing Guide Rails: These rails glide on LM Guide HSR Bearings (ตลับลูกปืน LM Guide HSR, which is the term in Thai) that run the length of the rail. Because of their low friction, they work wonderfully in situations that call for precision and rapidity.

- Roller Guide Rails: These rails feature rollers that extend the entire length of the rail. Because of their low friction, they work wonderfully in situations that call for precision and rapidity.

- Sliding Contact Guide Rails: Rails with a sliding contact that extends the whole length of the rail are one type of guide rail. They are perfect for uses requiring low speed and great accuracy due to their high friction.

Conclusion

When designing a linear guiding system, various considerations must be considered. These include the load type, the needed speed and precision, the operating environment, and the installation and maintenance needs. Given the complexity of the issue, it is recommended that you seek the advice of a seasoned engineer when deciding which linear guide type is most suited to your needs.